1. Application background

In recent years, with the rapid development of real estate, it has led to a sharp increase in market demand for wooden doors, furniture and home decoration industries. Since the woodworking industry is a traditional industry in China, the initial woodworking production is mainly based on manual and simple tool processing, the production efficiency is very low, and it can not meet the needs of the market, so the woodworking engraving machine came into being.

Woodworking engraving machine is mainly used in wooden doors and antique furniture and other industries, mainly for wood pattern, corrugated and hollow processing, which greatly improves the efficiency, accuracy and product consistency of traditional manual processing.

At present, most of the woodworking engraving machines used by furniture manufacturers are still stepper motor system, due to the low speed of the stepper motor, the stepper Angle distance ambassador engraving machine engraving speed is slow, and the engraving accuracy is poor, which directly affects the production efficiency and production quality of the furniture factory, and the stepper motor system is easy to lose step, and can not be corrected in time when errors occur. Resulting in the loss of materials. As a motion control system with high speed and high subdivision accuracy, AC servo system has unparalleled advantages here, but the AC servo price is more expensive, which is not conducive to reducing costs.

With many years of professional background in motion control industry, Lisan has developed ED series hybrid servo system, which effectively balances the contradiction between stepping and servo in speed, precision and price, and has a high cost performance. The hybrid servo motor of the system can reach 2000RPM under constant torque output, the encoder line number is 2500PPR, and the resolution of the motor per turn can reach 10000PPR after the control pulse 4 is subdivided by 4x frequency technology inside the driver. Obviously, both its speed and accuracy greatly exceed the requirements of the woodworking engraving machine.

2, electrical structure and process flow

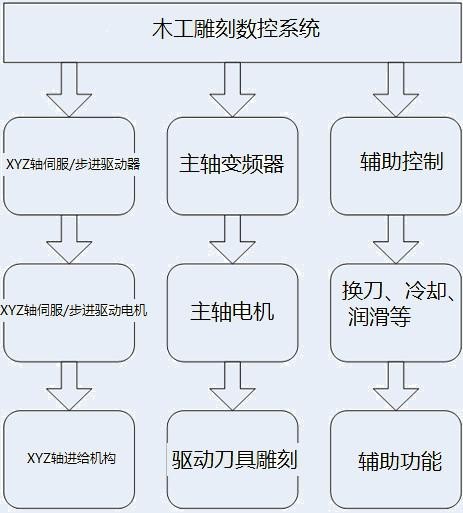

Woodworking engraving machine system generally includes the following parts:

Numerical control system: The customer has developed the numerical control system.

Spindle system: Integrated electric spindle, driven by frequency converter.

Feed drive system: ball screw, elastic coupling, linear guide rail, servo drive system.

Its topology is as follows:

Woodworking CNC engraving machine's working process consists of the following parts:

(1) The pattern and text information to be engraved are written into a program according to a standard instruction format and input into the computer.

(2) After processing and calculation, the computer sends the components of each coordinate axis to their respective driving circuits.

(3) The driving circuits drive the axes to rotate and provide feedback control to precisely position the spindle motor.

(4) Repeat the above steps to complete the engraving of the desired pattern or text.

LEESN Hybrid Servo System

Lishi's hybrid servo motor is equipped with an incremental photoelectric encoder (2500 lines or optional 1000 lines), which is compatible with Lishi hybrid servo drives. It completely solves the problem of step loss in open-loop stepper motors, improving the machine's processing speed and accuracy. With an optimized magnetic circuit design, high-quality cold-rolled silicon steel sheets, and high-temperature resistant permanent magnet materials, the motor's power density is increased, stability improved, and the motor's temperature rise significantly reduced. The product line includes various motor models ranging from 20 to 86 frames and 0.1NM to 12NM.

◆Product range covers 20 to 86 frames, fully compatible with the same model stepper motors

◆ Built-in incremental photoelectric encoder (2500 wire or 1000 wire optional)

◆ Large output torque, high speed

◆ Low heat, low noise, high efficiency

◆ High-speed stop smooth and fast, no zero speed oscillation running stable, vibration noise is small

◆ Fast response, suitable for frequent start-stop occasions

Field debugging result

The configuration scheme of Lisan company is (X/Y/Z) : 86 hybrid servo drive + 86 hybrid servo motor

Field tests have proved that the engraving speed is comparable to the servo motor, and the product ripple and smoothness are obviously superior to the stepper motor, which has a strong competitiveness.

Peroration

The application of LEESN hybrid servo system in engraving machine is of great significance for domestic electromechanical automation system technology to form a breakthrough in this industry. The project plays a very positive role in the high-end application of domestic brand stepper/servo system in the field of CNC engraving machine.

立三混合伺服系统在雕刻机上的应用,对于国产机电自动化系统技术在该行业形成突破具有重大意义。项目对国产品牌步进/伺服系统在数控雕刻机领域的高端应用起到十分积极的作用。