leesn closed-loop stepper motor solution for backlight fitting equipment

Company Name:

Project content:

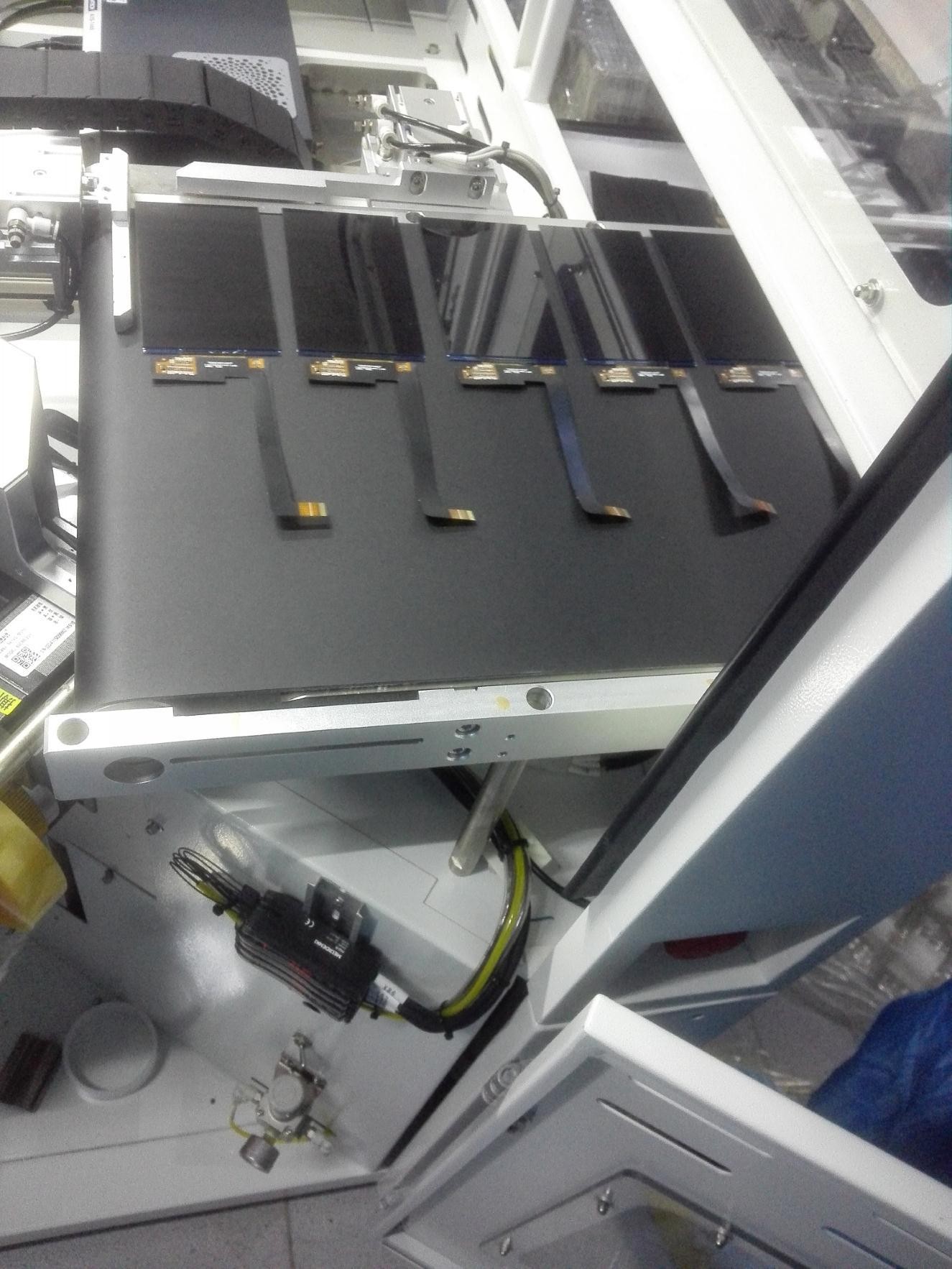

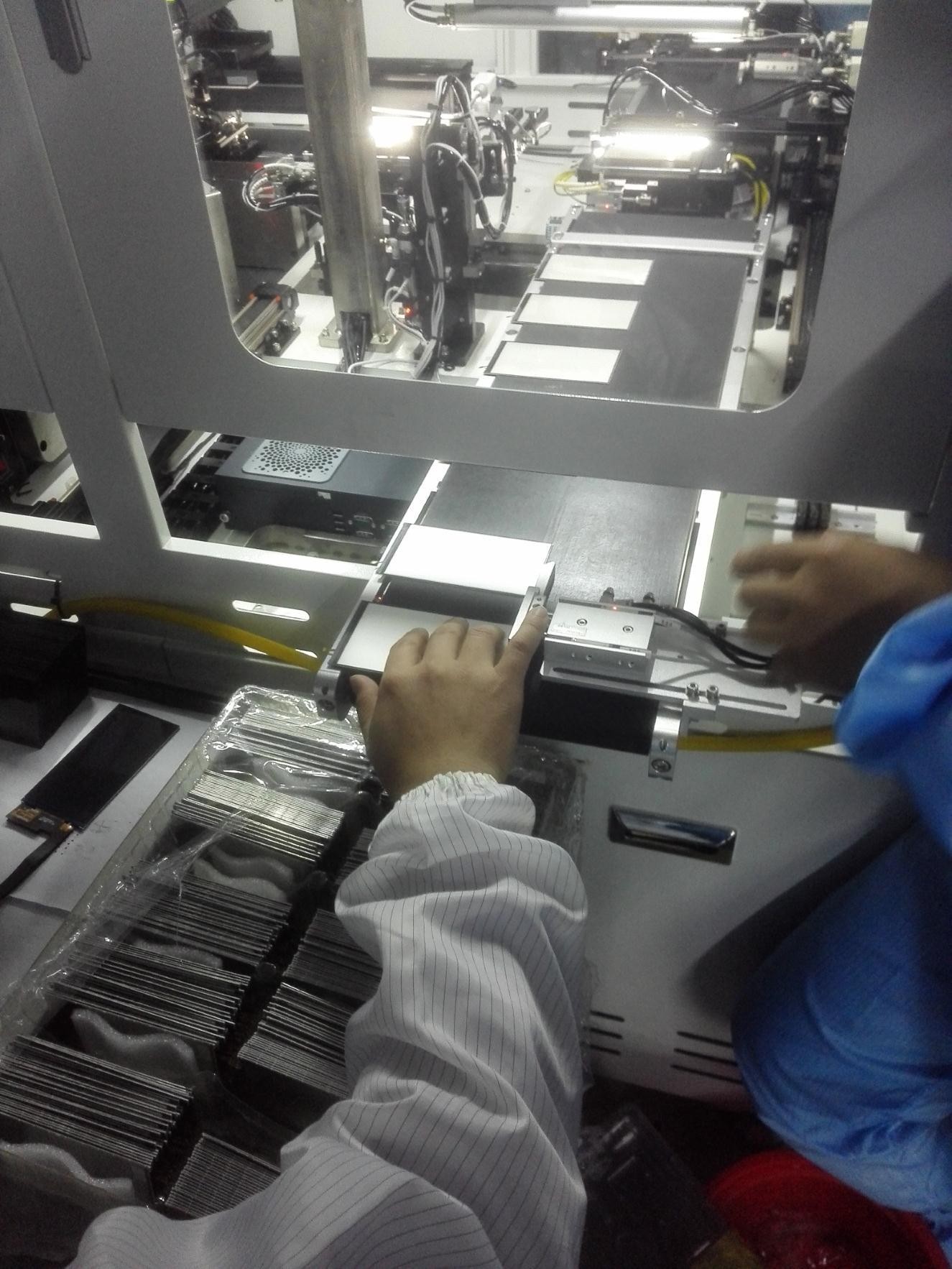

The transmission efficiency of both the white backlight and the black display is very important, even the decisive factor. How can we improve the efficiency of the Department while taking into account the cost performance? It is a headache for each equipment manufacturer.

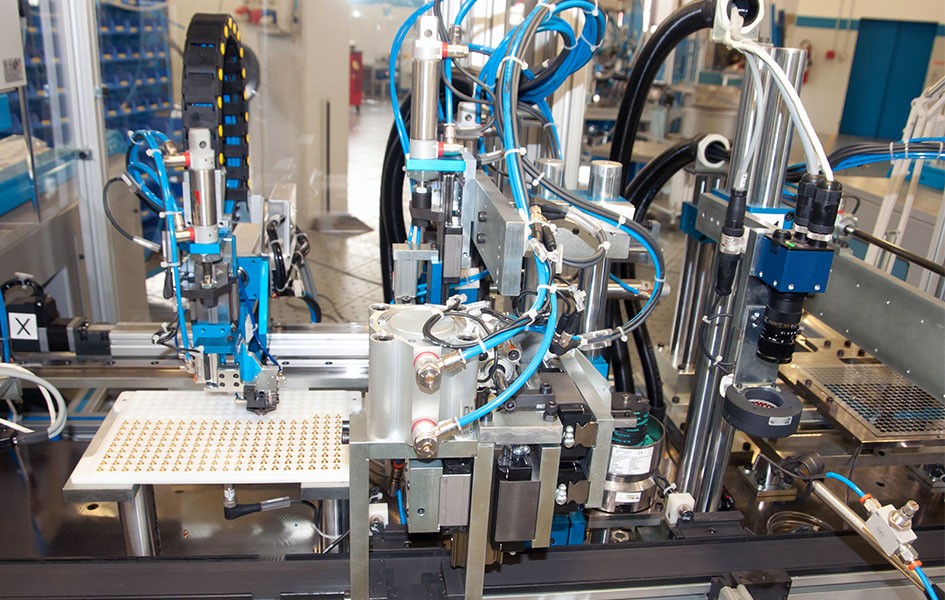

Vertical three closed-loop step scheme:

Backlight alternating transmission motor drive scheme: LS57-PLC+DE57

Display alternating transmission motor drive scheme :LS57-PLC+DE57

Detail+